In the Core Facility, the processes of climate change can be researched using isotope signatures on different time scales and their influence on ecosystems and humans can be better understood. In this way, new insights can be gained into how ecosystems have recovered after climate catastrophes, but also how modern climate change is altering precipitation in the Alps.

The Core Facility: Stable Isotopes at the Institute of Earth Sciences offers high-precision analysis functions for stable isotopes. The Core Facility allows fast and user-friendly analysis of solid and liquid samples with a state-of-the-art isotope ratio mass spectrometer (IRMS) via two peripheral preparation lines from Elementar Analysensysteme GmbH.

The laboratory offers the possibility to analyze δ13Cand δ18Oin carbonate phases as well as δ2Hand δ18Oanalysis in water, but also other liquid samples (e.g. urine, wine, juices, etc.) in a single processing line with continuous flow isotope ratio mass spectrometry (CF-IRMS).

In addition, the new core facility offers capabilities for combustion-based elemental analysis isotope ratio mass spectrometry (EA-IRMS) and high-temperature pyrolysis-based isotope analysis (HPT-IRMS). This purification line can analyze a variety of solid samples for their stable ratio of δ13C, δ15Nand δ34Sin EA-IRMS combustion mode and for δ2Hand δ18Oin HPT-IRMS pyrolysis mode. The system can analyze dry organic matter (such as plant and animal tissue), natural soil and sediment samples, through to a range of natural and industrial mineral phases and compounds.

The laboratory is equipped with all necessary standard reference materials to provide full analytical capabilities.

The facility is used for research, teaching and contract work. If you are interested in the NAWI Graz Core Facility: Stable Isotopes, please contact:

Ass.Prof. Dr. Gerald Auer (Email: gerald.auer(at)uni-graz.at)

Tel: ++43 (316) 380 5581

Sample requirements for carbonate analysis:

- Pure carbonates: 50 - 100 µg dry sample.

- Sediment samples should contain at least 50 - 100 µg pure carbonate in their dry mass.

- If you are interested in analyzing phosphate, dolomite or siderite samples, please contact the head of the Core Facility.

Sample requirements for water/liquid analysis:

- 200 µl sample is required for water/liquid analysis.

- If you are interested in analyzing liquids other than water, please contact the head of the Core Facility.

Sample requirements for EA-IRMS analysis:

- Please contact the head of the Core Facility for details. Depending on the sample type and the desired analyses, sample requirements and any necessary wet chemical sample preparation will be discussed individually.

Sample requirements for HTP-IRMS analyses:

- Please contact the head of the Core Facility for details. Depending on the sample type and the desired analyses, sample requirements and any necessary wet chemical sample preparation will be discussed individually.

Equipment

Elementalisoprime PrecisION®: This modern mass spectrometer enables high-precision stable isotope ratio measurements of hydrogen, carbon, nitrogen, oxygen and sulphur in continuous flow mode.

ElementarisoFLOW: Carbonate and liquid preparation line with automatic acid feed and gas chromatographic gas concentration trap using Elementar UltiTrap® technology. The isoFLOW is supplied with a fully automatic sampling arm and a heated sample tray that can process 180 samples simultaneously.

Elementaryvario PYRO cube®: Combined combustion and pyrolysis furnace with Advanced Purge and Trap (APT) technology. Elemental concentrations and stable isotope ratios of carbon, nitrogen and sulphur of solids are analyzed in combustion mode (= EA-IRMS analysis in CNS mode). Oxygen and hydrogen concentrations and stable isotopes are analyzed in pyrolysis mode (= HTP-IRMS analysis in OH mode).

Additional equipment

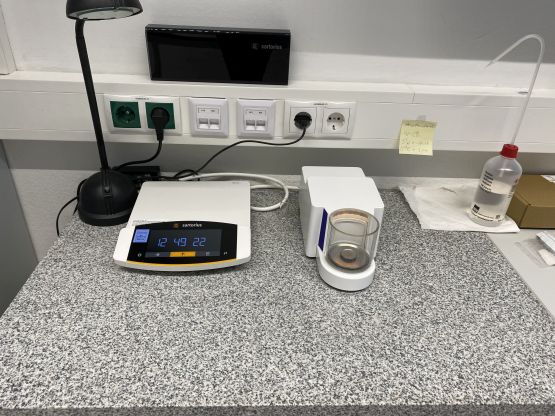

Sartorius MCE-Cubis® II High-precision balance for accurate sample weighing (readability up to 0.001 mg | 1 μg) for both EA-IRMS and carbonate analysis with CF-IRMS.

Gas lines and gas cabinets for the safe supply of all necessary high-purity monitoring gases (CO2, SO2, CO, H2, N2), equilibration gases (10% H2 in He, 5%CO2 in He) and process gases (He and O2 ). This includes permanently installed and personal gas warning sensors and the associated safety equipment.